Switches

Special switches

make controlling easier...

I choice to have touch-switches instead of normal tumblers or pushbuttons

for the following reasons:

-

Space saving: normal switches take

quite some space. As the control panel had to be rather compact, and

because of the large amount of switches and LED's, there just wasn't

enough room to place even miniature switches.

-

Money saving: a good-quality miniature

switch costs about 1.50 Euro, while I construct one touch-switch for

about 0.60 Euro.

|

|

Of course, touch-switches cost a lot of time and effort to construct, but the

money I saved was considerable: I needed about 300 switches, so this saved me

about 270 Euro!

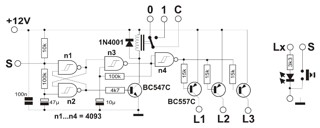

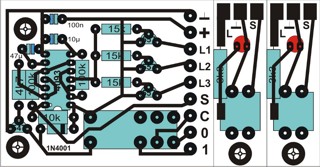

The switch itself reacts to body-part touching (i.e. a fingertip): This way

an interference signal is picked up. This is amplified and rectified by two

transistors. The condenser and resistor make a low-pass filter, so at the input

side of the 40106 a "clean" signal is present. The 40106 inverts the

signal to a proper digital output. Touching the sensor input generates a +5V

output. As there are 6 Schmitt-triggers in one 40106 package, on each circuit

board six of these schematics are build.

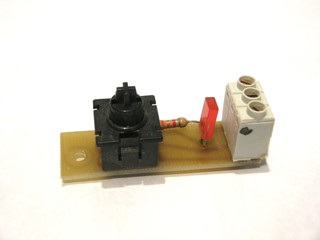

The contact point consists of a simple small brass nail. The flat head can be

touched; on the nail rod a short (to prevent interference) wire connects the

contact to the circuit board. The 3 mega-ohms resistor is added mainly for security

reasons: after all, it is to be touched safely, not to cause electrocution!

The Emergency buttons

I wanted to build them earlier, but as the layout became more complex and

less easy to reach to each part, it became an absolute necessity. As it happens

very frequently in real life, we seem to need to have a few accidents before

a problem gets fixed. This is not a real excuse, but I needed to have several

emergence buttons on the "outside" of the layout - the 'fascia'.

This wasn't constructed until the summer of 2004. By then some engines and cars

had reached the 'urgent repairing'-state.

|

|

|

|

|

|

|

|

About 15 red-colored pushbuttons where placed on the inside of the layout,

the control panels and on the fascia, and connected

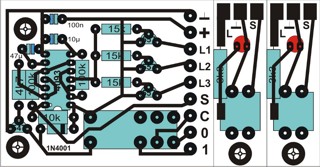

to the main circuit board. The schematic (left picture) shows this central board.

It receives a negative pulse from one of the pushbuttons. This sets the flip-flop

and causes the relay to disconnect the clock for all speed controllers, causing

all train traffic to stop at once. When this emergency condition is active,

LED's near the buttons start flashing. When one of the buttons is pressed again,

but longer (more than 5 seconds), the circuit resets, and the LED's light up

continuously. This allows the buttons to be found in the dark as well. The right

hand side picture shows an installed emergency button.