Moulds

Small series production in 3 dimensions

I needed moulds at a very early stage of my model railroad construction.

On constructing the platforms of the 'Boulroie' station, I needed platform sidings

following the Belgian example. As I planned about 18 yards of platform, I needed

about 30 yards of platform sidings (not all sidings are visible or need a 'real'

siding). So, series production was definitely useful.

The construction method was generally always the same: making a master model

(from styrene or carved from plaster), gluing it in a fitting box (I often use

my empty plastic cigar boxes), pouring the mould, letting it set, making castings.

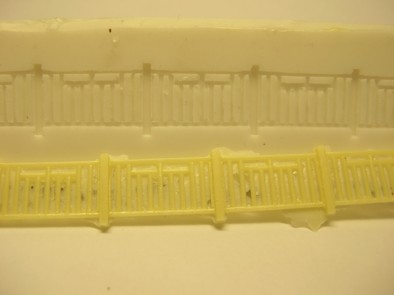

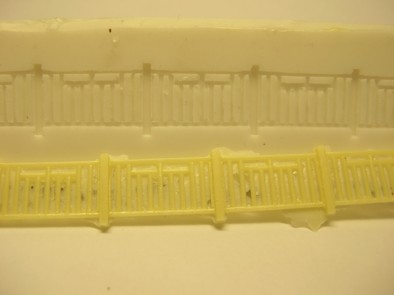

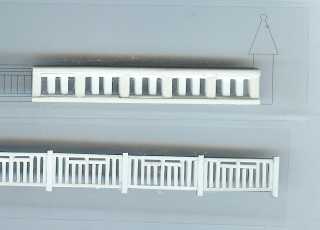

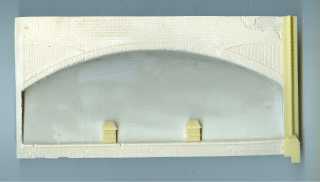

Above: some master models

In the beginning (2002), I used Latex rubber for the moulds. The advantages

and disadvantages are, in my opinion, the following:

- + : Cheap (about 10 Euro a liter)

- + : No mixing needed (Just poor it from the can)

- - : Lots of thin layers needed, with a 12 hour interval

- - : Ruptures after frequent use, especially when pouring smaller pieces

- - : Shrinks and loses flexibility after a while

- - : Needs special products when pouring synthetic materials

- - : Sensitive to sunlight and heat changes

In spite of the disadvantages I managed to pour a lot of plaster platform

sidings with it, as well as the retaining walls for the 'Boulroie' station.

I noticed I needed special products for synthetics (poly-urethane) when I wanted

to remove the casting from the mould. The mould was torn up completely and ended

in the dust bin...

That was one of the reasons for me to switch (in 2004) to silicon moulds (Neukasil

RTV 102):

- + : Can be poured in one session

- + : Very strong and flexible

- + : Very detailed castings are possible

- + : No special products needed to release the castings

- + : Stays the same (no deterioration)

- - : Rather expensive (about 35 Euro a liter)

- - : Precise mixing needed with second component. (5 to 10%, but my supplier

only sells 5% standard. So: accurate measuring, or buying more B-component)

- - : Rather long time needed to settle (a few days, but the shop-keeper

recommended a week)

- - : very sticky while pouring (can be messy)

As I said before, I make my casting using:

- Plaster: two parts of powder, one part of water and a little bit of acrylic

paint (this keeps the plaster a bit more firm and easier to work on)

- Synthetic: two-components polyurethane-mix (Neukadur multicast 5)

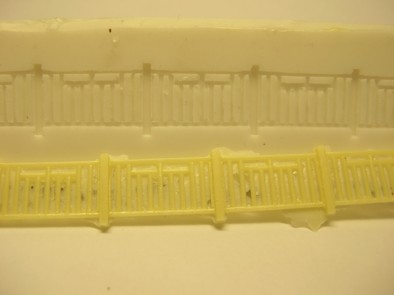

Examples of castings: plaster on the left, plastic right

Using this silicon molding rubber, I made new moulds for platform sidings (from

a new 'original' made from styrene), but also streets, typical Belgian railway

fences, attributes for the 'Boulroie' station...